50-size.belt drive

#1

Thread Starter

Hi,

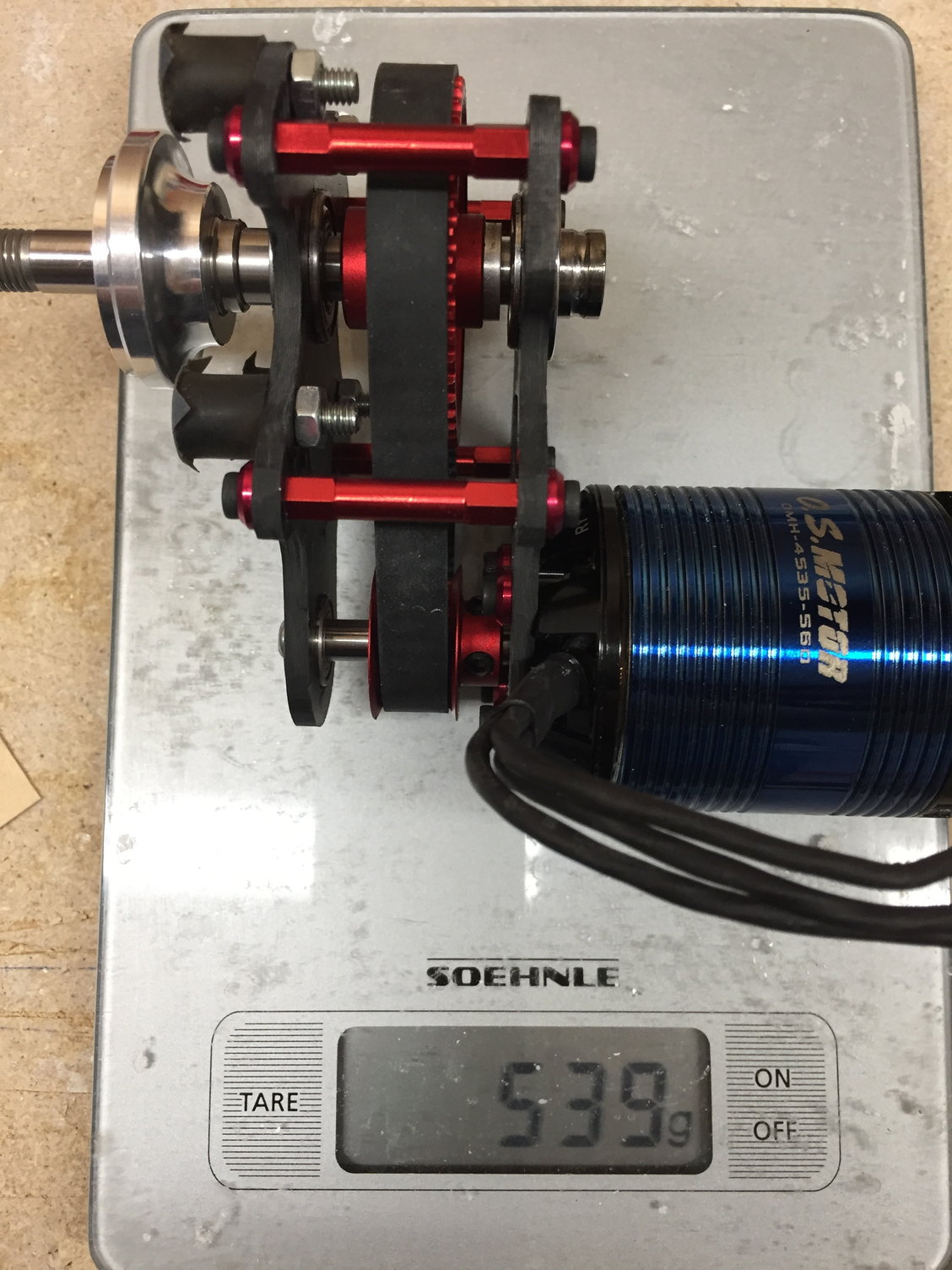

Influenced by OS belt drive, contra systems and lately AR Single drive, I made my own for Sebart Miss Wind 50E:

At least as powerful as Hacker A50-16S but lighter. Runs very smooth and cooling is easy to arrange.

Shaft and prop fastening are spares from Hacker. Belt and larger tooth wheel are from ebay. Motor and smaller tooth wheel are helicopter components from 380 size (Goblin 380 etc.).

Design and cf plates are my own.

Influenced by OS belt drive, contra systems and lately AR Single drive, I made my own for Sebart Miss Wind 50E:

At least as powerful as Hacker A50-16S but lighter. Runs very smooth and cooling is easy to arrange.

Shaft and prop fastening are spares from Hacker. Belt and larger tooth wheel are from ebay. Motor and smaller tooth wheel are helicopter components from 380 size (Goblin 380 etc.).

Design and cf plates are my own.

Last edited by ini; 09-14-2019 at 10:59 AM.

#3

My Feedback: (28)

Good job! How many grams? What prop are you turning? I was looking for an alternative to Hacker A50-16 but only found the 50 Products drive. Hard to justify the price on that one.

#4

Please forgive my total lack of knowledge. I understand the contra drives, I am trying to figure out what the advantage is to a belt drive on a non-contra setup. Of course you can change gearing, but you can get a different kv motor for that.

Adding a belt drive or gears has to add inefficiency and heat, compared to a direct drive, add to the weight and complexity (more things to go wrong), or at least thats why my little brain is telling me.

I'm sure there is a reason, I just can't figure it out

What am I missing?

Adding a belt drive or gears has to add inefficiency and heat, compared to a direct drive, add to the weight and complexity (more things to go wrong), or at least thats why my little brain is telling me.

I'm sure there is a reason, I just can't figure it out

What am I missing?

#5

I like the way you think, I too couldn't justify costs of the current reduction motors so, like you, I was inspired to do my own. It's a bit lighter that Adverun Single and using the Competition Pyro with a little different reduction, a bit more powerful as well. Still awaiting the airframe for the moment but bench tests are very good with the D3Motors ESC/Governor I had Adam set up for me. Contra is next on the agenda but still searching a nice benchtop lathe. Awesome that you've done this for a 50-size! I was thinking a contra for 50 size just because it would be cool to have but had no idea what to do about props. Good luck.

Last edited by ted32776; 09-14-2019 at 04:48 PM.

#6

Thread Starter

This drive was actually designed for 5S as I have plenty of those, half of 10S used in 2-meter planes.

Prop is APC-E 16x10, 16x12 is also possible.

Measured RPM in bench is a tad over 8000 1/min w. 16x10 with full pack.

Weight is 301 grams in configuration of the picture. Without prop drive (40 g), rubber insulators and back support it is 247 g. Bigger wheel could be made lighter but didn't bother, with this total weight.

I do not have actual weight of Hacker A50 but on web site it is stated to be 345 g. It is unclear whether that includes propdrive or not.

Starting point for all this was cooling. I used to have an AngelS 50E w. Hacker A50-14S. That was prone to overheating. A new slotted spinner could be the answer. Heat is also a symtom of lesser efficiency. My drive runs very cool indeed.

The above question of justification for all this is good. Why bother when the belt has friction and it becomes more complex?

The answer is in the nature of electrical motor, especially outrunner. A direct-drive motor has to be built heavy to provide enough torque and it still suffers when it is run at lower speeds with heavy load. A motor that runs faster works with significantly better efficiency and behaves better. This gives more benefit than is given away with belt. For me it is also an engineering challenge that is interesting. So, more power and longer flight times is the answer.

As an example a small RC heli Goblin Fireball has direct drive. The motor weighs 200 g. Similar sizes other helis use gearing and the typical motor weighs 70-80 g. Gearing is ~ 50 g or less.

I also have a bigger one in the works. Just wanted to test the concept with a smaller one first.

Prop is APC-E 16x10, 16x12 is also possible.

Measured RPM in bench is a tad over 8000 1/min w. 16x10 with full pack.

Weight is 301 grams in configuration of the picture. Without prop drive (40 g), rubber insulators and back support it is 247 g. Bigger wheel could be made lighter but didn't bother, with this total weight.

I do not have actual weight of Hacker A50 but on web site it is stated to be 345 g. It is unclear whether that includes propdrive or not.

Starting point for all this was cooling. I used to have an AngelS 50E w. Hacker A50-14S. That was prone to overheating. A new slotted spinner could be the answer. Heat is also a symtom of lesser efficiency. My drive runs very cool indeed.

The above question of justification for all this is good. Why bother when the belt has friction and it becomes more complex?

The answer is in the nature of electrical motor, especially outrunner. A direct-drive motor has to be built heavy to provide enough torque and it still suffers when it is run at lower speeds with heavy load. A motor that runs faster works with significantly better efficiency and behaves better. This gives more benefit than is given away with belt. For me it is also an engineering challenge that is interesting. So, more power and longer flight times is the answer.

As an example a small RC heli Goblin Fireball has direct drive. The motor weighs 200 g. Similar sizes other helis use gearing and the typical motor weighs 70-80 g. Gearing is ~ 50 g or less.

I also have a bigger one in the works. Just wanted to test the concept with a smaller one first.

Last edited by ini; 09-15-2019 at 12:52 AM.

#7

Thread Starter

Good work Ted. That looks very good too.

Something you could consider, and this also applies to Adverrun SD:

In my tests I found that in sudden change of direction, the prop alignment tends to change as rubber isolators flex. Because of this I had to bring the back support further away from prop to keep alignment decent and to make plane more stable.

Also, I put the back support in the center so that the torque of the motor will be handled by front rubber isolators, not the the back ones. This is not a big issue but need to be considered when installing the drive in the plane. If you keep it like that the back support of the plane need to be strong and stiff enough to cope with vertical forces induced.

Something you could consider, and this also applies to Adverrun SD:

In my tests I found that in sudden change of direction, the prop alignment tends to change as rubber isolators flex. Because of this I had to bring the back support further away from prop to keep alignment decent and to make plane more stable.

Also, I put the back support in the center so that the torque of the motor will be handled by front rubber isolators, not the the back ones. This is not a big issue but need to be considered when installing the drive in the plane. If you keep it like that the back support of the plane need to be strong and stiff enough to cope with vertical forces induced.

Last edited by ini; 09-15-2019 at 12:54 AM.

#8

Thread Starter

One benefit in this concept is that if you end up in situation where you want/need to change kV or behaviour of the drive, it is possible to change gearing. Normally you just change smaller tooth wheel and cf plates and the rest is kept as is.

There are more choices available than with current outrunners (+Plettenberg).

BTW, this is very silent. You can only hear the prop.

There are more choices available than with current outrunners (+Plettenberg).

BTW, this is very silent. You can only hear the prop.

#9

Interesting point. I suppose one could opt for a longer motor shaft and use a soft mounted bearing from the back of the motor. I have already changed the motor shaft for a longer one so I guess I can do it all again. Thanks, Ted.

#10

Thread Starter

Or you just put another two aluminum spacers in place of those back mount rubbers and connect back of those with a simple plate. Then install a rubber in the center of the plate.

#11

Yes, that might be the smart approach. Lately, I'm organizing a new build and somehow I've gotten stuck in this "weight saving mindset". Can't seem to shake the urge to over analyze every little thing to perhaps save a gram or two. Silly, I know, but there is that hope that I'll be pleasantly surprised by the total weight when finished and of course, by extension, I'll miraculously fly better, LOL. I flew F3c for twenty years and hardly ever gave a thought to increments of weight so this is a new challenge for me, for sure and I like challenges. When I see what some of the top pilots' models weighed at WC, it just drives me a little harder. I can't have their fingers or brains but at least I can strive to have some of the other advantages.

#12

Hi Guys

INI I think we spoke off this at the Nordic Champ i Finland this summer?

I have started to collect parts for this!

I'm going to make one for a 2M airframe and are going to use the 3GT belt from a OS belt drive.

What I have troubbel to find a good selction off is the gear wheels that are first cheap and light weigt , where do you find this ?

I have thinking to use parts that are mostly already made (as I dont have a lathe in my workshop) the frame for this I plan to make out off 3mm carbonplates

INI I think we spoke off this at the Nordic Champ i Finland this summer?

I have started to collect parts for this!

I'm going to make one for a 2M airframe and are going to use the 3GT belt from a OS belt drive.

What I have troubbel to find a good selction off is the gear wheels that are first cheap and light weigt , where do you find this ?

I have thinking to use parts that are mostly already made (as I dont have a lathe in my workshop) the frame for this I plan to make out off 3mm carbonplates

#13

Hi Guys

INI I think we spoke off this at the Nordic Champ i Finland this summer?

I have started to collect parts for this!

I'm going to make one for a 2M airframe and are going to use the 3GT belt from a OS belt drive.

What I have troubbel to find a good selction off is the gear wheels that are first cheap and light weigt , where do you find this ?

I have thinking to use parts that are mostly already made (as I dont have a lathe in my workshop) the frame for this I plan to make out off 3mm carbonplates

INI I think we spoke off this at the Nordic Champ i Finland this summer?

I have started to collect parts for this!

I'm going to make one for a 2M airframe and are going to use the 3GT belt from a OS belt drive.

What I have troubbel to find a good selction off is the gear wheels that are first cheap and light weigt , where do you find this ?

I have thinking to use parts that are mostly already made (as I dont have a lathe in my workshop) the frame for this I plan to make out off 3mm carbonplates

Take a look /at this web siteand you will see different types of sprokets and belt sices/toothing..

https://www.gearsandsprockets.co.uk

#14

Rune, be aware that sprockets have different toothing which require belt suited for the special type of sprocket.

Take a look /at this web siteand you will see different types of sprokets and belt sices/toothing..

https://www.gearsandsprockets.co.uk

Take a look /at this web siteand you will see different types of sprokets and belt sices/toothing..

https://www.gearsandsprockets.co.uk

#15

Thread Starter

That'sright Rune, we did talk about this earlier in July.

I will gather some information and come back to you.

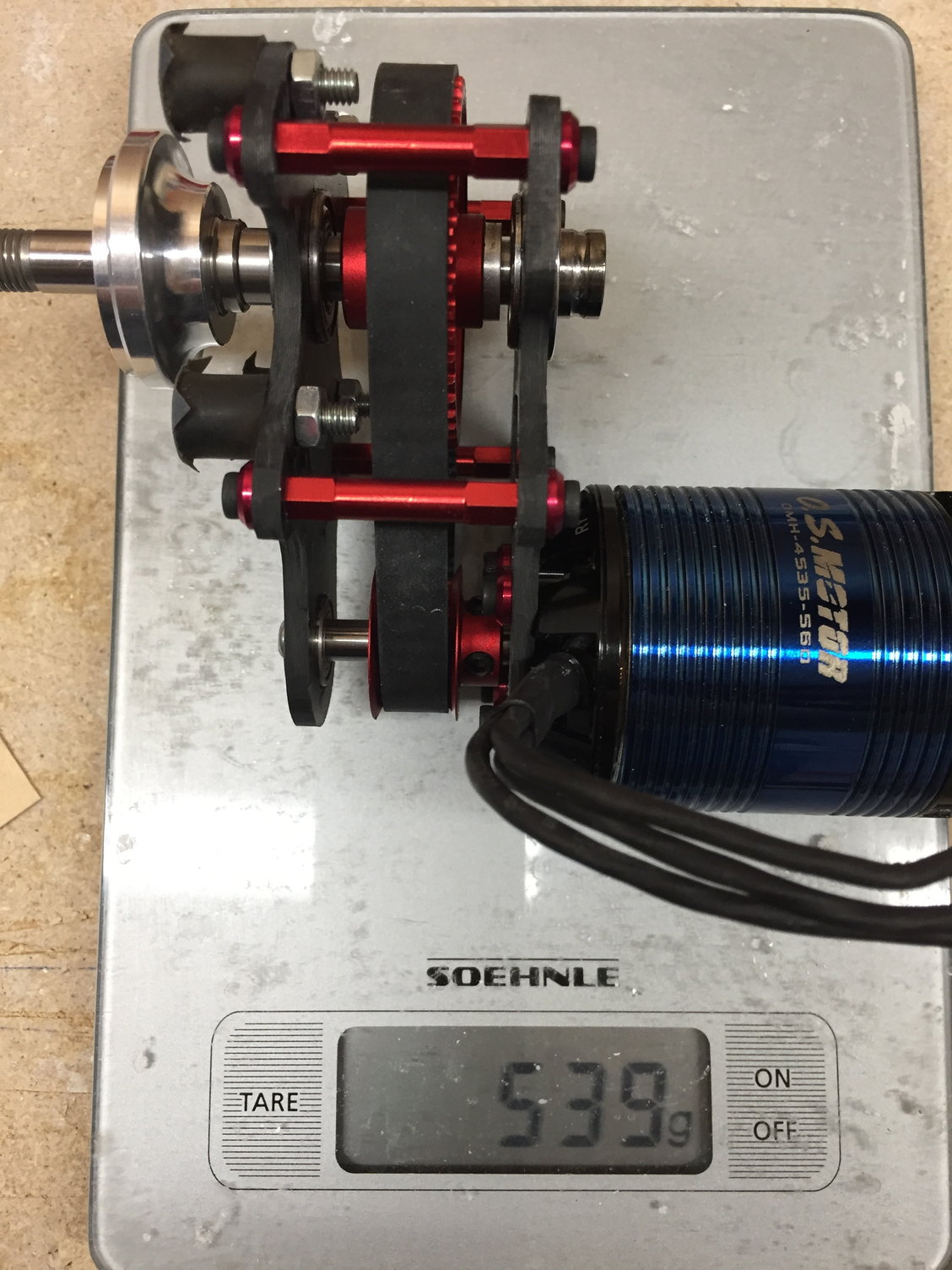

I have a larger unit ready for bench testing and the air frame is also ready to accept it. Current weight is just under 500 g with prop drive & rubber grommets.

The tests may cause some modifications.

I will gather some information and come back to you.

I have a larger unit ready for bench testing and the air frame is also ready to accept it. Current weight is just under 500 g with prop drive & rubber grommets.

The tests may cause some modifications.

#16

RuneG, all you have to do is go to the heli market. SAB and others all use 3mgt belts in their top level machines. Belts can be bought online from various sources if you need another length [which you will unless you plan to incorporate an idler]. These parts are dirt cheap and well machined. Typically they are designed for 10mm and larger shafts but that's an easy mod to accomplish. Motor pulleys are also available from industrial sources at reasonable prices although the number of teeth are limited in selection so ultimately, you will have to carefully select your motor Kv.

#18

Tomas L.....Mike at F3A Unlimited has a "front mount conversion kit" made by MAXX products for mounting a Himax pattern motor from the front rather than standard rear mount. This kit will have a very nice hollow 8mm shaft with very light prop adapter included.

#19

Hello guys!

I have now about 30 flights on my drive and I'm very happy about the performance .

But its one thing I'm a bit concern about and that is the temp.off the motor!

All the flights have been in about 0 degreeds and the motor is a bit to hot for me!

I have use an Os motor but is thinking about change tha to a kontonikk .

At this point I use the OS esc and has 20 degreds timing has ATV on ca 75% and get around 75 A .

Has someone som experience with similar Kontronikk motors, about cooling, The OS seems a bit "closed"

I have now about 30 flights on my drive and I'm very happy about the performance .

But its one thing I'm a bit concern about and that is the temp.off the motor!

All the flights have been in about 0 degreeds and the motor is a bit to hot for me!

I have use an Os motor but is thinking about change tha to a kontonikk .

At this point I use the OS esc and has 20 degreds timing has ATV on ca 75% and get around 75 A .

Has someone som experience with similar Kontronikk motors, about cooling, The OS seems a bit "closed"

#21

有限会社ヨシカワ (50products.com) These guys seem to be promoting smaller gear and belt drives in Japan. Their products are very good quality.

#22

Hello guys!

I have now about 30 flights on my drive and I'm very happy about the performance .

But its one thing I'm a bit concern about and that is the temp.off the motor!

All the flights have been in about 0 degreeds and the motor is a bit to hot for me!

I have use an Os motor but is thinking about change tha to a kontonikk .

At this point I use the OS esc and has 20 degreds timing has ATV on ca 75% and get around 75 A .

Has someone som experience with similar Kontronikk motors, about cooling, The OS seems a bit "closed"

I have now about 30 flights on my drive and I'm very happy about the performance .

But its one thing I'm a bit concern about and that is the temp.off the motor!

All the flights have been in about 0 degreeds and the motor is a bit to hot for me!

I have use an Os motor but is thinking about change tha to a kontonikk .

At this point I use the OS esc and has 20 degreds timing has ATV on ca 75% and get around 75 A .

Has someone som experience with similar Kontronikk motors, about cooling, The OS seems a bit "closed"

What temp is the motor? When i used to race RC cars in stock class we added timing to get more RPM out of the motor and get more speed. We added timing until the motor was 80-90deg in the end of a heat. So up to 80-90deg is ok for a motor.